Designing, manufacturing and transporting two static gas mixers

South Pars Oil and Gas Company

Phases 20 & 21

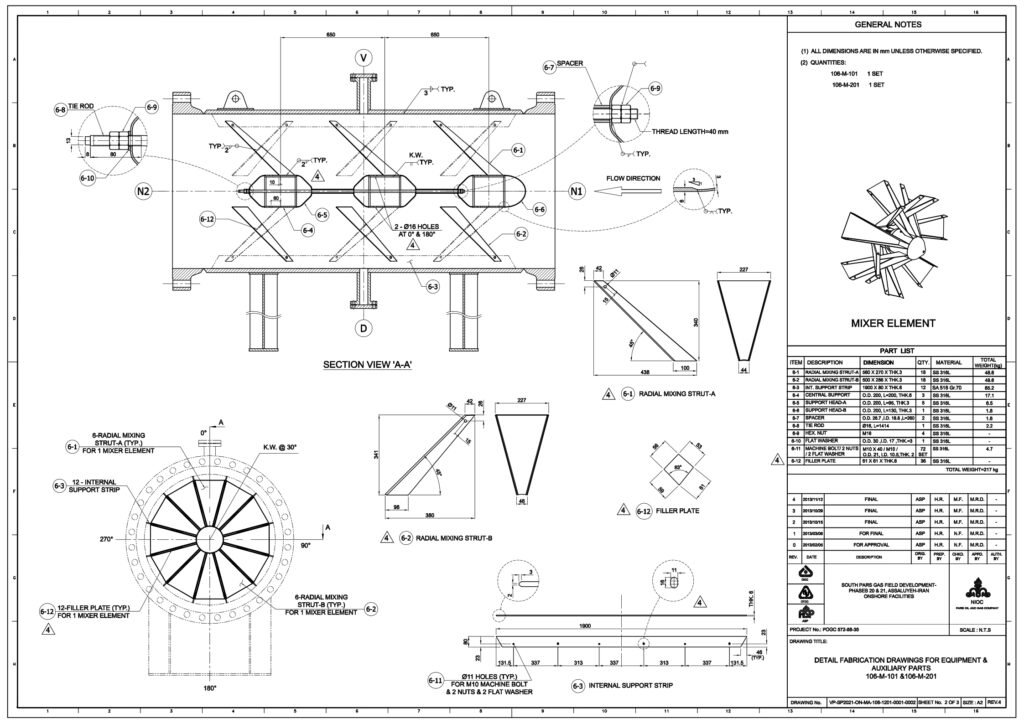

It should be noted that most of the companies that manufacture static mixers only have the ability to design and manufacture this equipment up to a diameter of 10 inches, and the said mixer is considered a part of special equipment even at the global level. The family of fixed equipment under pressure, without having a rotating part and relying only on fluid flow, mixes two incoming fluids together. The main or internal part of this equipment plays a key role in this function, and each of the manufacturers of this type of equipment has its own technical knowledge and unique design in this part, and on the other hand, due to the complexity of the operation of this equipment and complete dependence The design of the internal part according to the type and parameters of the fluid flow, it is practically not possible to copy this equipment, and for each order, the internal parts of this equipment must be designed from the beginning and based on the needs of that project. For the first time in Iran, this company succeeded in producing the technical knowledge of designing and manufacturing this equipment, relying on its engineering and production capabilities, and with its unique design, it succeeded in producing one of the largest fixed mixers with a diameter of 40 inches and a capacity of 900 cubic meters. per hour, the direction of phases 20 and 21 is South Pars.

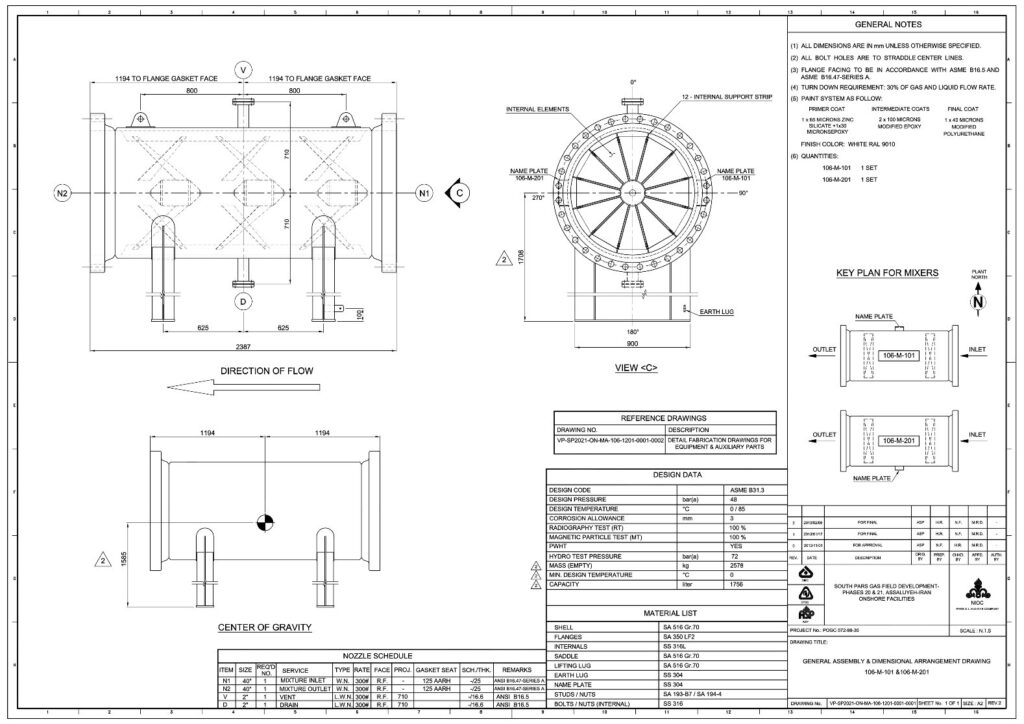

Scope of Work: Designing (including basic design), Manufacturing & Shipment of 40″ Static Gas Mixers

Client: South Pars Oil and Gas Company (POGC)

Engineering Consultant: OIEC / OTCC Company

Qty: 2

Material: SA-516 70N, SA-240 tp 316L, SA-350 LF2

Maximum Weight (t): 5,3

Maximum Length (mm): 2,387

Maximum Diameter: 40″

Maximum Pressure (bar): 48