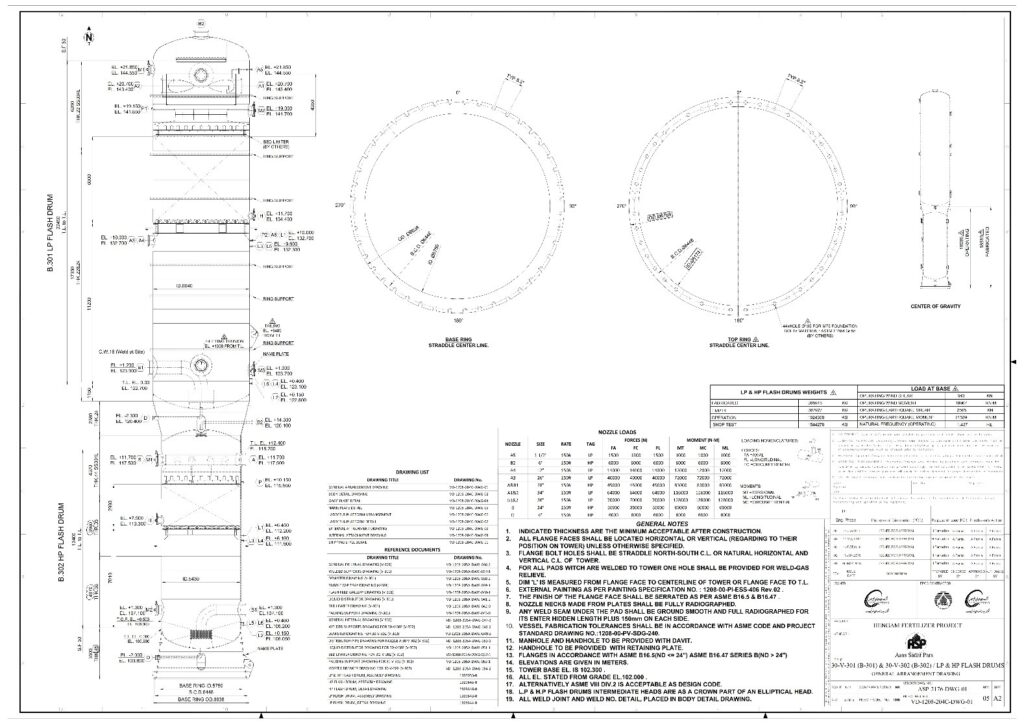

Design and construction of Flash-drum process tower

Hengam Petrochemical Complex

The flash drum process tower, which has been one of the imported and outsourced items for petrochemical projects, is one of the critical items in the ammonia and urea production process.

Regardless of the huge dimensions of this equipment, the nature of the process and its very complex geometry, along with the corrosiveness of the fluid during this process, has made this equipment one of the most challenging and imported items for urea and ammonia projects.

This tower consists of two separate process chambers with capacities of 855 and 330 cubic meters, each of which is made of carbon steel and stainless steel parts, as well as cooled nozzles and nickel chrome base intermediate connections.

This process works in near vacuum conditions and is responsible for the separation of hydrogen gas.

Scope of Work: Design and Manufacturing of T-204C (Flash drum) Tower

Client: Hengam Petrochemical Complex

Engineering Consultant: Pidec Company

Qty: 1

Maximum Weight (t): 288

Material: SA-516 70 & 60, SA-240 Tp 304L, NiCrFe3

Maximum Length (mm): 45m

Maximum Diameter (mm): 6700

Maximum Pressure (bar): 0.6